Grooved Rails

When rails are required for service in paved or grassed locations, grooved rails provide an excellent solution.

Grooved Rails were invented by Alphonse Loubat in 1852 for use in the Tram systems being introduced in New York and Paris at that time. In these cities, the new trains had to share the streets with carts and pedestrians. The solution was to embed the rails in the street so that their running surfaces were at street level. Since wheel flanges were still necessary, a solution was required to protect the flanges while keeping the flange slot as narrow as possible. This was to protect horses and humans from tripping and prevented feet and narrow cart wheels from being trapped between the rails and the road surface.

Basic Dimensions

| Profiles | Weight | Head width | Height | Base width | Web | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg/m | lb/yd | mm | in | mm | in | mm | in | mm | in | ||||||

| 51R1 (Ri52) | 51.37 | 103.56 | 113.00 | 4.45 | 130.00 | 5.12 | 150.00 | 5.91 | 12.00 | 0.47 | |||||

| 53R1 (Ri53) | 52.98 | 106.80 | 113.00 | 4.45 | 130.00 | 5.12 | 150.00 | 5.91 | 12.00 | 0.47 | |||||

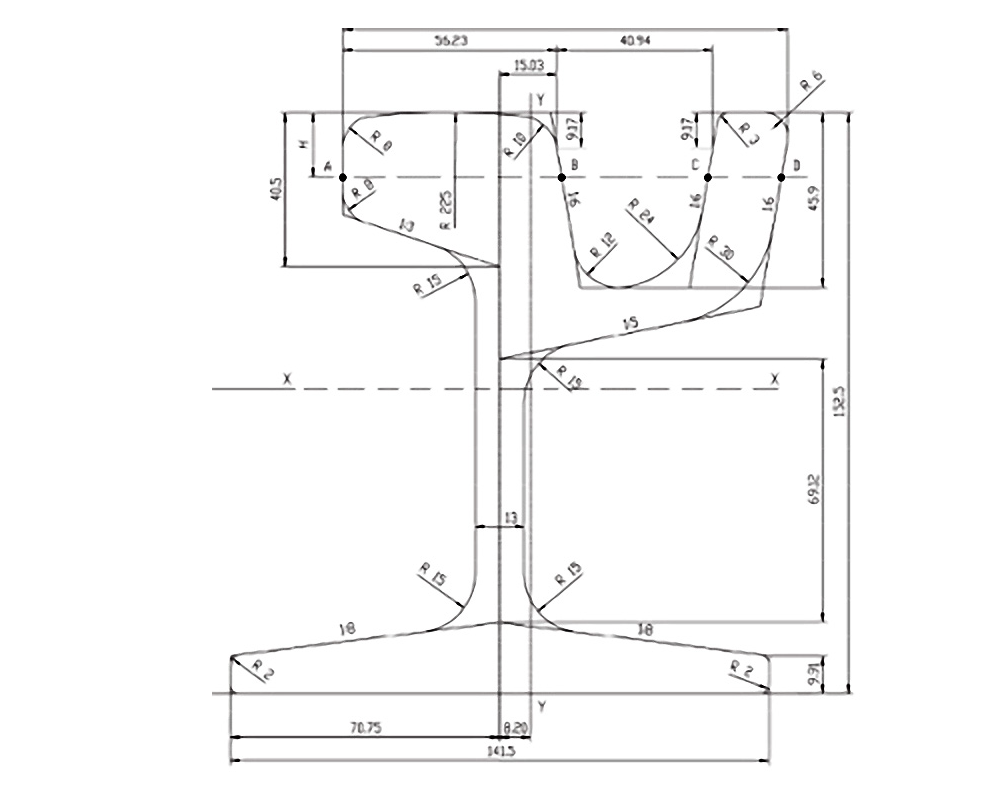

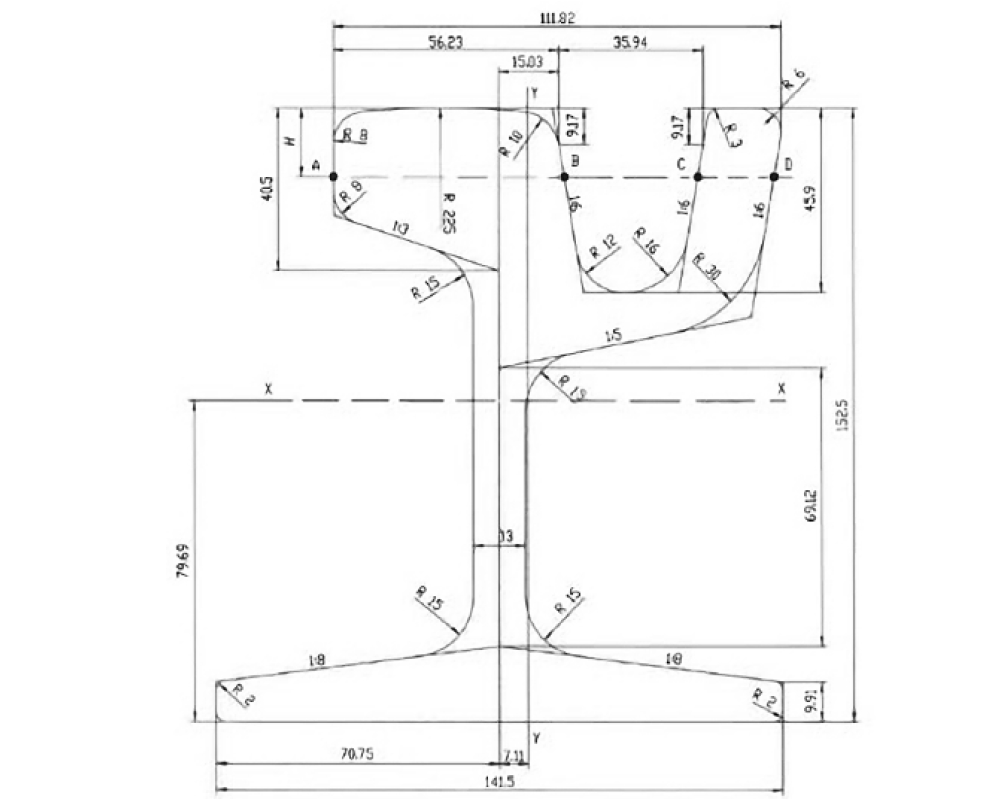

| 54G1/54R1 (41GPU) | 54.26 | 109.38 | 116.82 | 4.60 | 152.50 | 6.00 | 141.50 | 5.57 | 13.00 | 0.51 | |||||

| 54G2 (Ri54G2) | 54.55 | 109.97 | 116.60 | 4.59 | 152.50 | 6.00 | 141.50 | 5.57 | 13.00 | 0.51 | |||||

| 55G1 (35GP) | 54.77 | 110.41 | 111.82 | 4.40 | 152.50 | 6.00 | 141.50 | 5.57 | 13.00 | 0.51 | |||||

| 55G2 (41GP10) | 55.33 | 111.62 | 116.82 | 4.60 | 152.50 | 6.00 | 141.50 | 5.57 | 13.00 | 0.51 | |||||

| 55G3 (41GP13) | 55.27 | 111.62 | 116.82 | 4.60 | 152.50 | 6.00 | 141.50 | 5.57 | 13.00 | 0.51 | |||||

| 55R1 (Ri55NK) | 55.45 | 111.78 | 113.00 | 4.45 | 150.00 | 5.91 | 150.00 | 5.91 | 12.00 | 0.47 | |||||

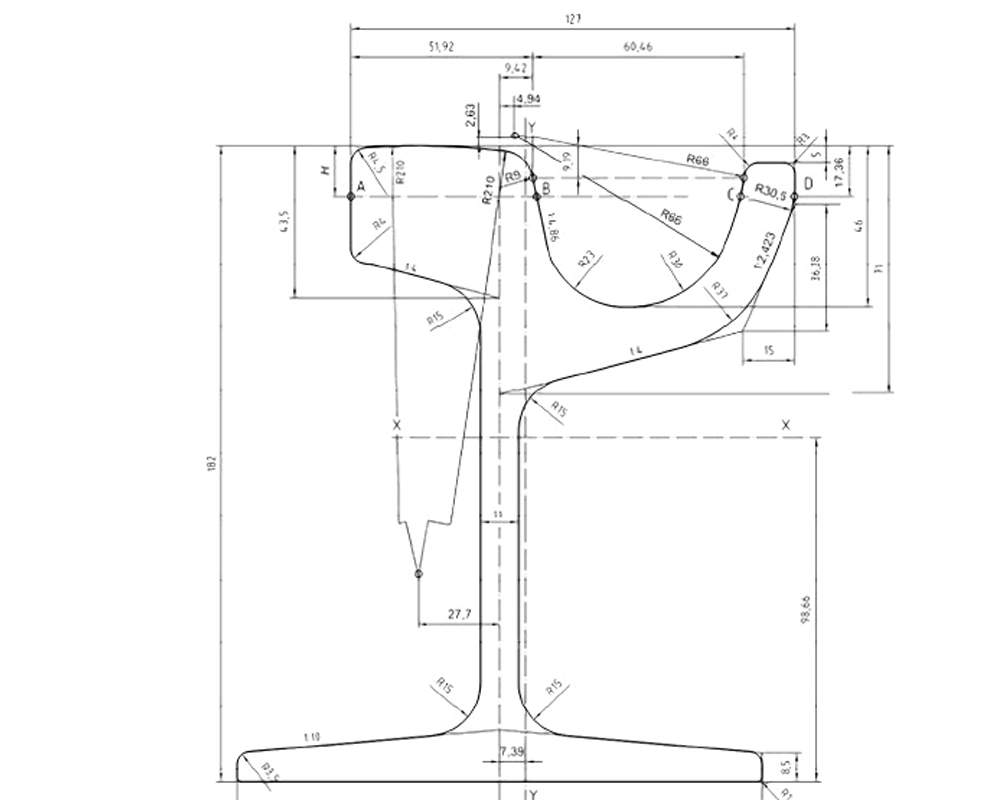

| 57R1 (Ri60N) | 56.54 | 113.98 | 127.00 | 5.00 | 182.00 | 7.17 | 150.00 | 5.91 | 11.00 | 0.43 | |||||

| 59R1 (Ri59) | 58.97 | 118.88 | 113.00 | 4.45 | 180.00 | 7.09 | 180.00 | 7.09 | 12.00 | 0.47 | |||||

| 59R2 (Ri59N) | 58.14 | 117.20 | 113.00 | 4.45 | 180.00 | 7.09 | 180.00 | 7.09 | 12.00 | 0.47 | |||||

| 60R1 (Ri60) | 60.59 | 122.14 | 113.00 | 4.45 | 180.00 | 7.09 | 180.00 | 7.09 | 12.00 | 0.47 | |||||

| 60R2 (Ri60N) | 59.75 | 120.45 | 113.00 | 4.45 | 180.00 | 7.09 | 180.00 | 7.09 | 12.00 | 0.47 | |||||

| 62R1 (NP4aM) | 62.37 | 125.73 | 116.00 | 4.57 | 180.00 | 7.09 | 180.00 | 7.09 | 12.00 | 0.47 | |||||

| 62R2 (Np4aS) | 61.91 | 124.80 | 116.00 | 4.57 | 180.00 | 7.09 | 180.00 | 7.09 | 12.00 | 0.47 | |||||

| 67R1 (Ph37a) | 66.76 | 134.58 | 135.00 | 5.31 | 180.00 | 7.09 | 180.00 | 7.09 | 13.00 | 0.51 | |||||

| 73C1 (VKRi60) | 72.73 | 146.62 | 113.10 | 4.45 | 180.00 | 7.09 | 180.00 | 7.09 | 12.00 | 0.47 | |||||

Mechanical properties

| Grade | Tensile Strength MPa | Elongation % | Hardness HB |

|---|---|---|---|

| R200 | ≥ 680 | ≥ 14 | 200 - 240 |

| R200V | ≥ 690 | ≥ 15 | 200 - 240 |

| R260 | ≥ 880 | ≥ 10 | 260 - 300 |

| R260V | ≥ 890 | ≥ 11 | 260 - 300 |

| R290V | ≥ 960 | ≥ 10 | 290 - 330 |

Chemical composition

| Grade | C % | Si % | Mn % | P % | S % | Cr % | V % |

|---|---|---|---|---|---|---|---|

| R200 | 0.40 - 0.60 | 0.15 - 0.58 | 0.70 - 1.20 | ≤ 0.035 | ≤ 0.035 | ≤ 0.15 | n/a |

| R200V | 0.30 - 0.48 | 0.15 - 0.58 | 0.70 - 1.20 | ≤ 0.035 | ≤ 0.035 | ≤ 0.15 | 0.08 - 0.20 |

| R260 | 0.62 - 0.80 | 0.15 - 0.58 | 0.70 - 1.20 | ≤ 0.025 | ≤ 0.025 | ≤ 0.15 | n/a |

| R260V | 0.45 - 0.58 | 0.15 - 0.58 | 0.70 - 1.20 | ≤ 0.025 | ≤ 0.025 | ≤ 0.15 | 0.08 - 0.20 |

| R290V | 0.45 - 0.58 | 0.15 - 0.58 | 1.00 - 1.25 | ≤ 0.025 | ≤ 0.025 | ≤ 0.15 | 0.08 - 0.20 |

Description

The best solution to the question of tripping safety was to roll a tough steel groove into the head of the rail. This allowed the road surface to abut the rail, while not interfering with the train wheels. These rails all share a bifurcated head, with a running surface on one side and a guard on the other. The guard carries no weight and serves only to maintain a minimum groove for the wheel flanges as they roll along.

Grooved rails are often referred to as tram, groove, grooved, girder or block rails. This family of rails is noted for two typical designs. The taller girder type rail with the familiar “I“ shape, and a more compact block design that incorporates the head and foot into a “block” of steel, eliminating the web. The groove is common to both.

The main difference between the two designs is that block rails have a shallow profile (depth), offering reduced excavation for installation. This is especially helpful when considering relocation of utilities in heavy urban environments.

As a very old style of rail, many Grooved rail profiles and grades have been developed over the years. The designs described in this website are available for new projects or replacement.