Crane Rails

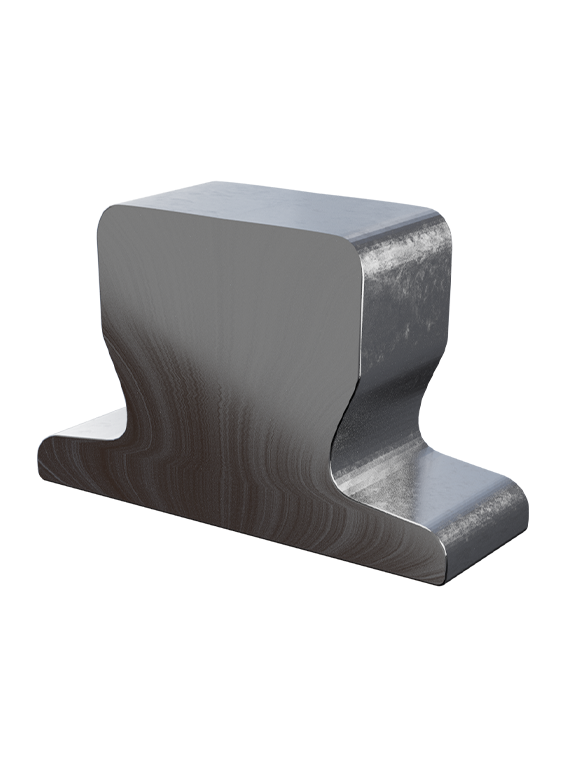

Crane Rails are an important subset of the rail industry. Their shapes can be quite different from those of Transport rails and are the result of a long evolution to give the rails specific performance characteristics.

Transverse loads (across the rails) are particularly high in crane applications and have led to rails with wide bases and relatively thick webs. Several profiles have flat heads as well, to better support large wheel loads.

Because each crane project is different, over time, many heavy crane rail profiles have been developed. American Heavy Crane Rails are the most common in North America, European DIN Rails are found worldwide, and Speciality Crane Rails appear for specific projects.

Basic Dimensions

| Profiles | Weight | Head width | Height | Base width | Web | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg/m | lb/yd | mm | in | mm | in | mm | in | mm | in | ||||||

| A75S | 63.61 | 128.23 | 75.00 | 2.95 | 85.00 | 3.35 | 200.00 | 7.87 | 75.00 | 2.95 | |||||

| MRS73 | 73.63 | 148.43 | 70.00 | 2.76 | 157.00 | 6.18 | 146.00 | 5.75 | 32.00 | 1.26 | |||||

| MRS86 | 85.50 | 172.36 | 102.00 | 4.02 | 102.00 | 4.02 | 165.00 | 6.50 | 80.30 | 3.16 | |||||

| MRS87A (PRI85) | 86.80 | 175.00 | 101.60 | 4.00 | 152.40 | 6.00 | 152.40 | 6.00 | 34.90 | 1.37 | |||||

| MRS125 | 125.00 | 251.99 | 120.00 | 4.72 | 180.00 | 7.09 | 180.00 | 7.09 | 40.00 | 1.57 | |||||

| MRS140 | 139.80 | 281.82 | 120.00 | 4.72 | 150.00 | 5.91 | 220.00 | 8.66 | 80.00 | 3.15 | |||||

| MRS192 | 192.00 | 387.05 | 140.00 | 5.51 | 157.20 | 6.19 | 229.00 | 9.02 | 128.30 | 5.05 | |||||

| MRS221 | 221.40 | 446.32 | 220.00 | 8.66 | 160.00 | 6.30 | 220.00 | 8.66 | 145.00 | 5.71 | |||||

| CR73 | 73.30 | 147.77 | 100.00 | 3.94 | 135.00 | 5.31 | 140.00 | 5.51 | 32.00 | 1.26 | |||||

| CR100 | 100.20 | 201.99 | 120.00 | 4.72 | 150.00 | 5.91 | 155.00 | 6.10 | 39.00 | 1.54 | |||||

| CR140 | 139.80 | 281.82 | 150.00 | 5.91 | 150.00 | 5.91 | 200.00 | 7.87 | 80.00 | 3.15 | |||||

| AS86 | 85.88 | 173.13 | 101.60 | 4.00 | 152.46 | 6.00 | 150.00 | 5.91 | 35.00 | 1.38 | |||||

| SP100 | 89.05 | 179.52 | 100.00 | 3.94 | 150.00 | 5.91 | 150.00 | 5.91 | 38.00 | 1.50 | |||||

| SP120 | 118.28 | 238.44 | 120.00 | 4.72 | 170.00 | 6.69 | 170.00 | 6.69 | 44.00 | 1.73 | |||||

Mechanical properties

| Grades | Tensile Strength MPa | Yield Strength MPa | Elongation % | Hardness (info only) HB |

|---|---|---|---|---|

| 70 kg (700) | ≥ 690 | ≥ 355 | ≥ 12 | ≥ 200 |

| 90 kg (900) | ≥ 880 | ≥ 440 | ≥ 8 | ≥ 260 |

| 110 CrV (1100) | ≥ 1080 | ≥ 640 | ≥ 7 | ≥ 320 |

| R340 | ≥ 1150 | ≥ 600 | ≥ 7 | ≥ 340 |

Chemical composition

| Grades | C % | Mn % | Si % | P % | S % | V % | Cr % |

|---|---|---|---|---|---|---|---|

| 70 kg (700) | 0.40 – 0.60 | 0.80 – 1.20 | ≤ 0.350 | ≤ 0.045 | ≤ 0.045 | n/a | n/a |

| 90 kg (900) | 0.60 – 0.80 | 0.80 – 1.30 | ≤ 0.500 | ≤ 0.045 | ≤ 0.045 | n/a | n/a |

| 110 CrV (1100) | 0.65 – 0.85 | 0.90 – 1.30 | ≤ 0.500 | ≤ 0.040 | ≤ 0.040 | 0.05 – 0.15 | 0.20 – 0.80 |

| R340 | 0.80 - 0.95 | 0.90 - 1.40 | ≤ 0.500 | ≤ 0.045 | ≤ 0.045 | 0.05 - 0.15 | 0.20 - 0.80 |

Description

There is a long history of crane rail development and many profiles were developed for specific applications over a century ago. Having proven to be effective, these are still in demand today for special applications. In addition, new rail profiles have also been developed to meet new needs in industrial and port applications. Wirth Rail distributes a wide range of these ‘singular’ profiles. Although the producers may have changed, these rails meet or exceed the original mill specifications.

Special Crane Rails are usually produced to Mill specifications. The grades are the same as those found in European Crane rail, with the most common being the 70 kg, 90 kg and the alloy grades 110 CrV and R340.

Special Crane Rails are finished in standard lengths of 9, 10, 12, 15 and 18 metres (≈ 30, 33, 39, 49 and 59 ft), but other lengths can be supplied by special request. Rail ends are prepared with the usual non-drilled (blank), square-finished ends. Mitre cutting and drilling are also available, again by special request. As with the DIN rails, not all profiles can be drilled due to their unusual shapes and webs.

All Crane rails are produced and tested to stringent metallurgical quality standards. They are offered in multiple grades which improve the rail’s load-bearing capabilities while reducing in-service wear rates. The grading of Crane Rails depends on their origins: in North America, Brinell Hardness is used for grading purposes, whereas the European standards focus on Tensile Strength. There is an approximate correlation between the two systems.