Crane Rails

Crane Rails are an important subset of the rail industry. Their shapes can be quite different from those of Transport rails and are the result of a long evolution to give the rails specific performance characteristics.

Transverse loads (across the rails) are particularly high in crane applications and have led to rails with wide bases and relatively thick webs. Several profiles have flat heads as well, to better support large wheel loads.

Because each crane project is different, over time, many heavy crane rail profiles have been developed. American Heavy Crane Rails are the most common in North America, European DIN Rails are found worldwide, and Speciality Crane Rails appear for specific projects.

Basic Dimensions

| Profiles | Weight | Head width | Height | Base width | Web | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kg/m | lb/yd | mm | in | mm | in | mm | in | mm | in | ||||||

| A45 | 22.10 | 44.55 | 45.00 | 1.77 | 55.00 | 2.17 | 125.00 | 4.92 | 24.00 | 0.94 | |||||

| A55 | 31.80 | 64.11 | 55.00 | 2.17 | 65.00 | 2.56 | 150.00 | 5.91 | 31.00 | 1.22 | |||||

| A65 | 43.10 | 86.89 | 65.00 | 2.56 | 75.00 | 2.95 | 175.00 | 6.89 | 38.00 | 1.50 | |||||

| A75 | 56.20 | 113.29 | 75.00 | 2.95 | 85.00 | 3.35 | 200.00 | 7.87 | 45.00 | 1.77 | |||||

| A100 | 74.30 | 149.78 | 100.00 | 3.94 | 95.00 | 3.74 | 200.00 | 7.87 | 60.00 | 2.36 | |||||

| A120 | 100.00 | 201.59 | 120.00 | 4.72 | 105.00 | 4.13 | 220.00 | 8.66 | 72.00 | 2.83 | |||||

| A150 | 150.30 | 302.99 | 150.00 | 5.91 | 150.00 | 5.91 | 220.00 | 8.66 | 80.00 | 3.15 | |||||

Mechanical properties

| Grades | Tensile Strength MPa | Yield Strength MPa | Elongation % | Hardness (for information only) HB |

|---|---|---|---|---|

| 70 kg (700) | ≥ 690 | ≥ 355 | ≥ 12 | ≥ 200 |

| 90 kg (900) | ≥ 880 | ≥ 440 | ≥ 8 | ≥ 260 |

| 110 CrV (1100) | ≥ 1080 | ≥ 640 | ≥ 7 | ≥ 320 |

| R340 | ≥ 1150 | ≥ 600 | ≥ 7 | ≥ 340 |

Chemical composition

| Grades | C % | Mn % | Si % | P % | S % | V % | Cr % |

|---|---|---|---|---|---|---|---|

| 70 kg (700) | 0.40 – 0.60 | 0.80 – 1.20 | ≤ 0.350 | ≤ 0.045 | ≤ 0.045 | n/a | n/a |

| 90 kg (900) | 0.60 – 0.80 | 0.80 – 1.30 | ≤ 0.500 | ≤ 0.045 | ≤ 0.045 | n/a | n/a |

| 110 CrV (1100) | 0.65 – 0.85 | 0.90 – 1.30 | ≤ 0.500 | ≤ 0.040 | ≤ 0.040 | 0.05 – 0.15 | 0.20 – 0.80 |

| R340 | 0.80 – 0.95 | 0.90 – 1.40 | ≤ 0.500 | ≤ 0.045 | ≤ 0.045 | 0.05 – 0.15 | 0.20 – 0.80 |

Description

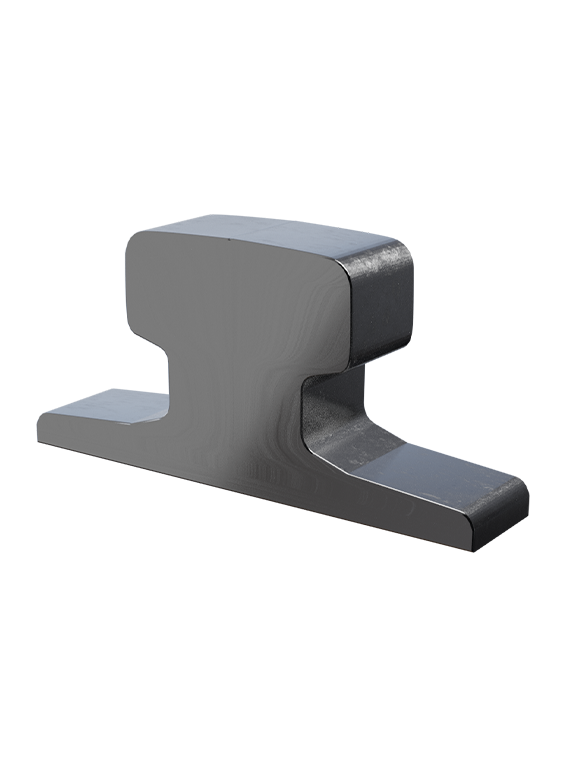

A class of short and squat rails was developed in Europe and is described by the DIN 536 Standard. Commonly referred to as “DIN” rails, these are found worldwide and are, by volume, the most widely used crane rails in the world.

DIN rails are offered in a range of sizes, from A45 (22.1kg/m) to A150 (150.3 kg/m) and can fulfill the requirements of most crane rail systems. Unlike the names of many other rails, the nomenclature for DIN rails describes the width of the head and not its weight (for example, A45 has a 45mm wide head).

Each DIN rail profile is characterized by a low center of gravity, a relatively wide and robust head and a very wide web and base. Designed to be installed on beams or foundations that offer continuous support, their lower height can be a boon for installations where overhead clearance is important. Their width and blocky shapes are extremely stable — ideal for crane applications.

The DIN 536 standard defines two steel grades: one with a tensile strength greater than 690 MPa and one greater than 880 MPa. Over time, different mills have come to use different jargon to represent these grades. Wirth Rail’s DIN rail supplier, ArcelorMittal, uses the names 70 kg & 90 kg. (aside: 880 MPa = 880 N/mm2 ˜ ( 90 kg x gravitational constant 9.81m/s2 )/mm2).

Two additional grades are found in Europe but are not described in the DIN 536 specification. The steel is alloyed with Chromium and Vanadium to achieve a tensile strength greater than 1080 MPa. ArcelorMittal refers to these by the names 110 CrV and R340 in its literature.

European heavy crane rails are finished in standard lengths of 9, 10, 12, 15 and 18 metres (≈ 30, 33, 39, 49 and 59 ft). Other lengths can be supplied by special request. The stocky shapes of these rails make drilling impractical. Square-finished ends are standard with Mitre cuts also available.

All Crane rails are produced and tested to stringent metallurgical quality standards. They are offered in multiple grades which improve the rail’s load-bearing capabilities while reducing in-service wear rates. The grading of Crane Rails depends on their origins: in North America, Brinell Hardness is used for grading purposes, whereas the European standards focus on Tensile Strength. There is an approximate correlation between the two systems.